Testing is another vital part of equipment maintenance. It involves subjecting the machinery to various operational conditions to evaluate its performance, reliability, and compliance with standards. Through load testing, stress testing, or functional testing, technicians can assess the equipment’s capacity, stability, and overall functionality. This helps identify any weaknesses or limitations, allowing for necessary adjustments or upgrades.

NDT (Non-Destructive Testing) testing is another crucial aspect of equipment inspection. It involves using various techniques to examine the integrity and quality of materials or structures without causing damage. NDT methods, such as ultrasonic testing, radiographic testing, or magnetic particle testing, can detect hidden defects or flaws that may not be visible to the naked eye. This type of testing is especially important for safety-critical components or structures, such as pressure vessels or lifting equipment.

Pressure Tests:

- Hoses

- Pipes

- Tubes

- Valves

- Air Tanks

Hydro test Services:

- Hydro test Cylinders

- Hydro test of Bowser’s

- Hydro test of Tanks

- Hydro test of Pipelines

- Hydro test of Pressure Vessels

- Inspection of Witness of Hydro test etc.

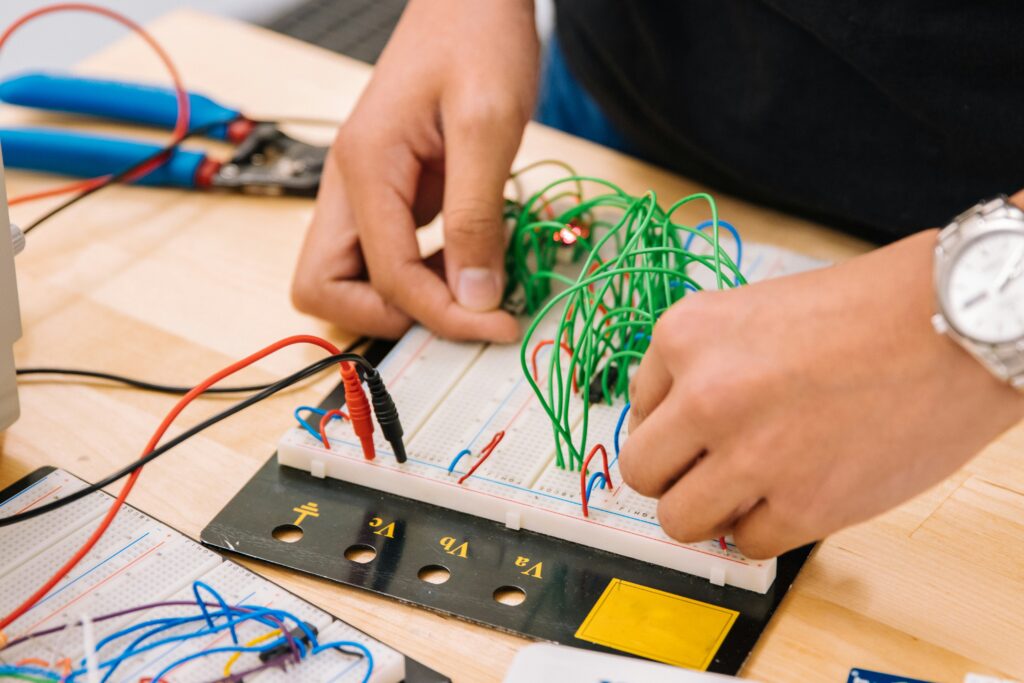

Electrical Testing:

- Conformity checks

- Measurement of floor systems

- Thermal imaging

- Testing of mobile devices

Non-Destructive Testing (NDT):

- Mechanical and Vibration Tests (MVT)

- Ultrasonic Thickness Gauging (UTG)

- Dye Penetration Testing (DPT)

- Magnetic Particle Inspection (MPI)

- Ultrasonic Flaw Detection (UFD)